Explore the cutting-edge STAL technology that powers our operations and sets new benchmarks in the nickel extraction industry.

At TGEM, innovation drives sustainability. STAL Technology is a proprietary hydrometallurgical process that enables sustainable nickel production from laterite ore and industrial waste materials, such as spent catalyst and electronic waste. With a zero-waste approach, STAL maximizes resource utilization while minimizing environmental impact. As a result, it offers a scalable, sustainable solution for nickel production.

Initially designed for laterite ore processing, STAL Technology now also enables efficient nickel extraction from industrial waste materials, further enhancing sustainability and resource efficiency.

STAL delivers scalability, efficiency, and sustainability, making it a high-performance solution for modern nickel production.

STAL designed for rapid implementation and faster ramp-up time, supporting small-to-medium-scale mining concessions.

STAL capable of processing laterite ore (limonite to saprolite) and industrial waste materials for optimized material efficiency.

STAL ensures all residues can be repurposed into valuable by-products, minimizing environmental impact.

STAL achieves up to 95% nickel recovery (yield), while also extracting other valuable materials from feedstocks.

STAL optimizes acid consumption and operational resources, ensuring cost-effectiveness and sustainability.

STAL incorporates laterite ore and industrial waste feedstocks to create a more sustainable production ecosystem.

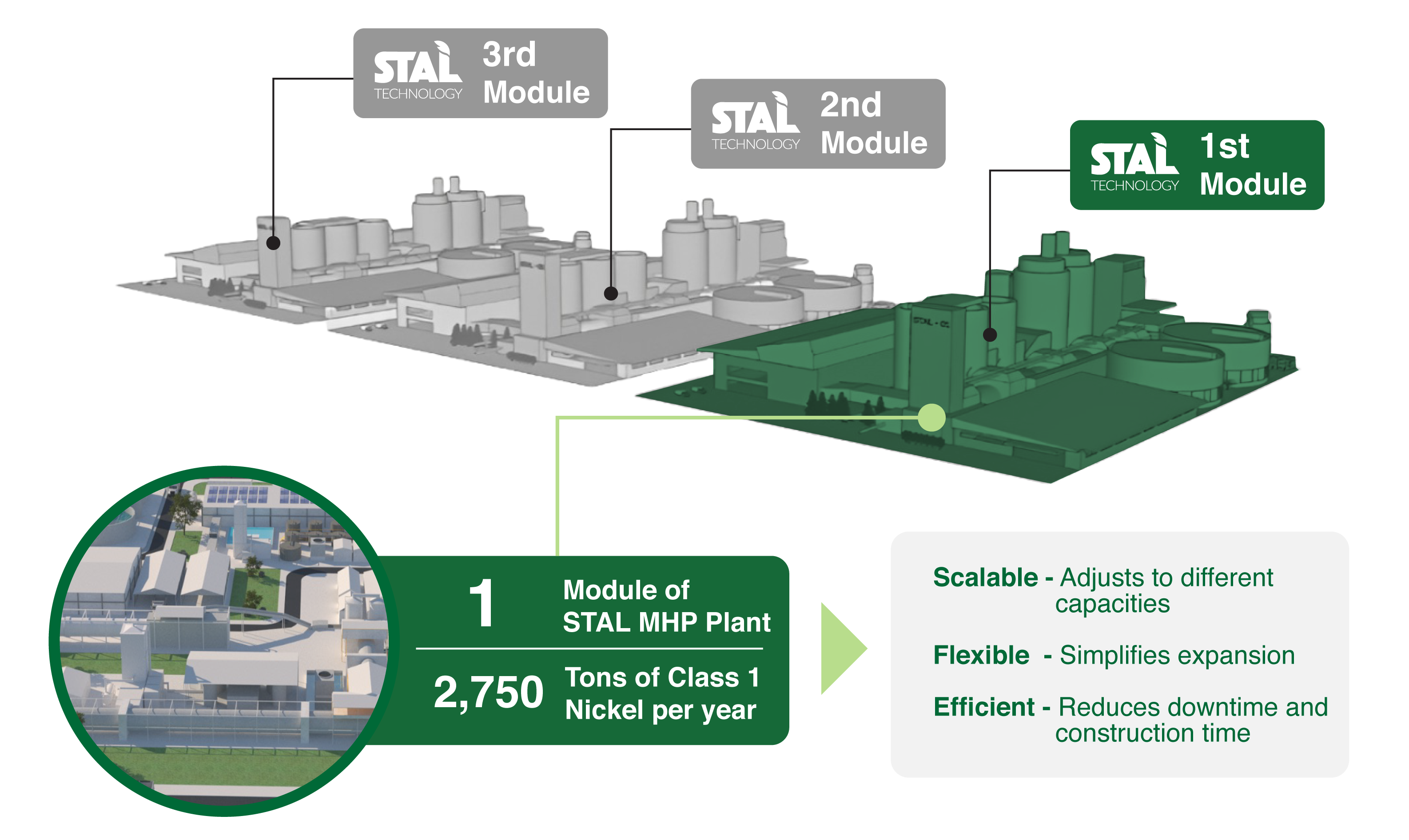

STAL’s modular system for laterite ore processing is designed for rapid implementation, scalable operations, and flexible expansion—enabling adaptable solutions that efficiently meet global nickel demand while remaining ideal for small-to-medium-scale mining concessions.

STAL Technology is integral to TGEM’s sustainability initiatives and is integrated across our nickel production projects, reinforcing TGEM’s commitment to responsible nickel extraction and innovation-driven growth. As part of this commitment, dive deeper into the technological advancements that define TGEM’s approach to nickel extraction