IGNITE Ecopark is set to revolutionize the nickel industry with its innovative and eco-friendly production facilities in Southwest Papua.

IGNITE Ecopark is designed to be a scalable, full-scale industrial ecosystem featuring multiple modules. The park aims to produce between 50,000 to 100,000 tons of Class 1 Nickel per year, equivalent to 200,000 to 400,000 tons of MHP annually. This high output capacity underscores the park’s efficiency and scalability, with a comprehensive layout aimed at efficient and sustainable production.

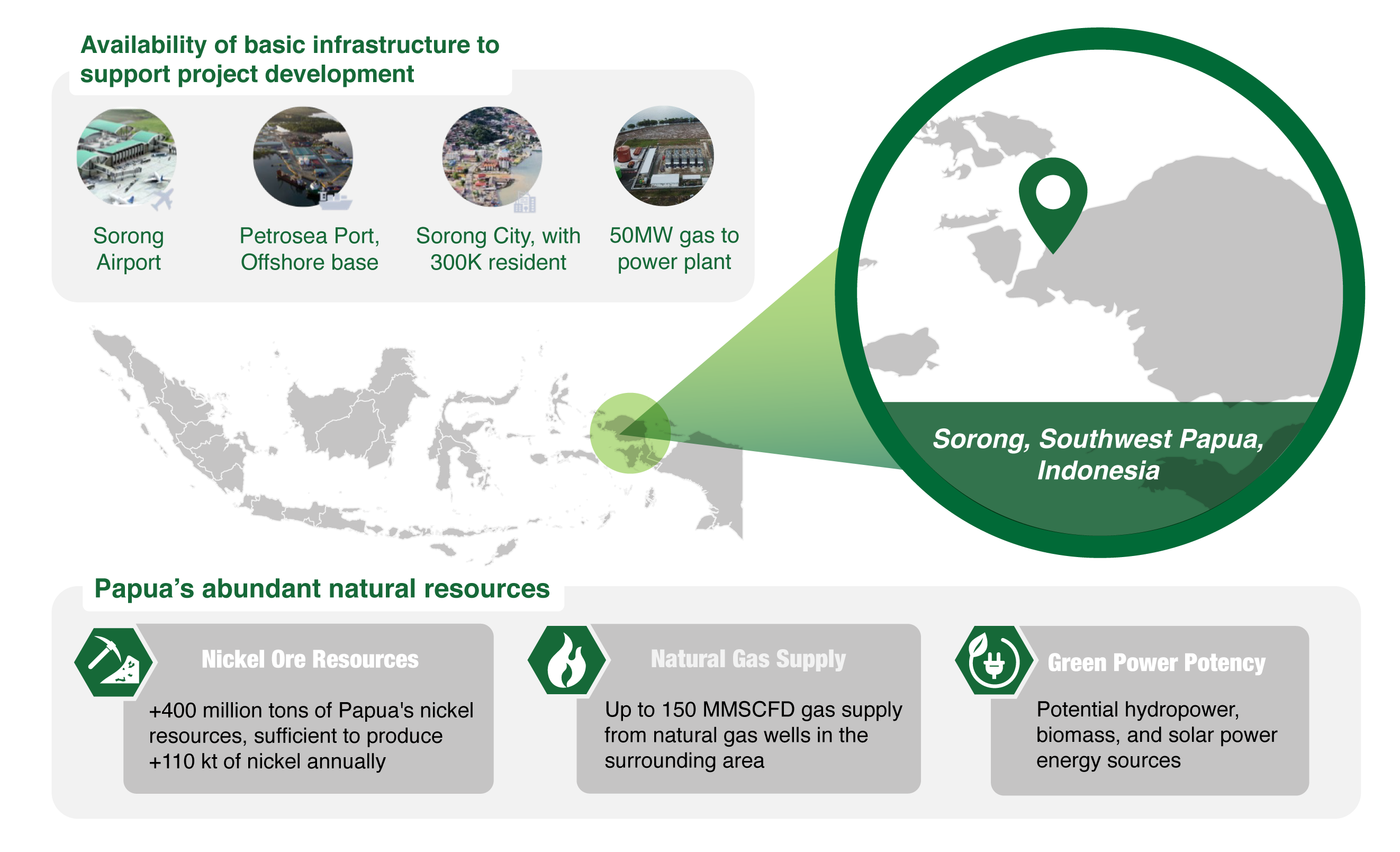

Located in the Sorong Special Economic Zone, IGNITE Ecopark benefits from proximity to abundant nickel laterite resources and natural gas, ensuring long-term operational efficiency and success.

IGNITE Ecopark is designed with advanced STAL technology to potentially achieve significant reductions in carbon footprint and water consumption. Our vision includes a zero waste initiative to process all residues into valuable by-products, demonstrating our commitment to environmental stewardship.