Explore the cutting-edge technology that powers our operations and sets new benchmarks in the nickel extraction industry.

STAL Technology, developed exclusively by TGEM, utilizes advanced hydrometallurgical processes to produce high-quality Class 1 Nickel efficiently and sustainably.

From exceptional efficient to our sustainable, zero-waste approach, discover the competitive edges that make STAL Technology stand out.

Faster ramp-up time and suitable for Indonesia’s nickel mining profile

Ability to process a variety of feedstock

100% residue converted into valuable by-products

Up to 95% nickel and cobalt recovery (yield)

Significantly reduced net acid consumption from initial usage

Creating a sustainable & ESG-compliant outcome

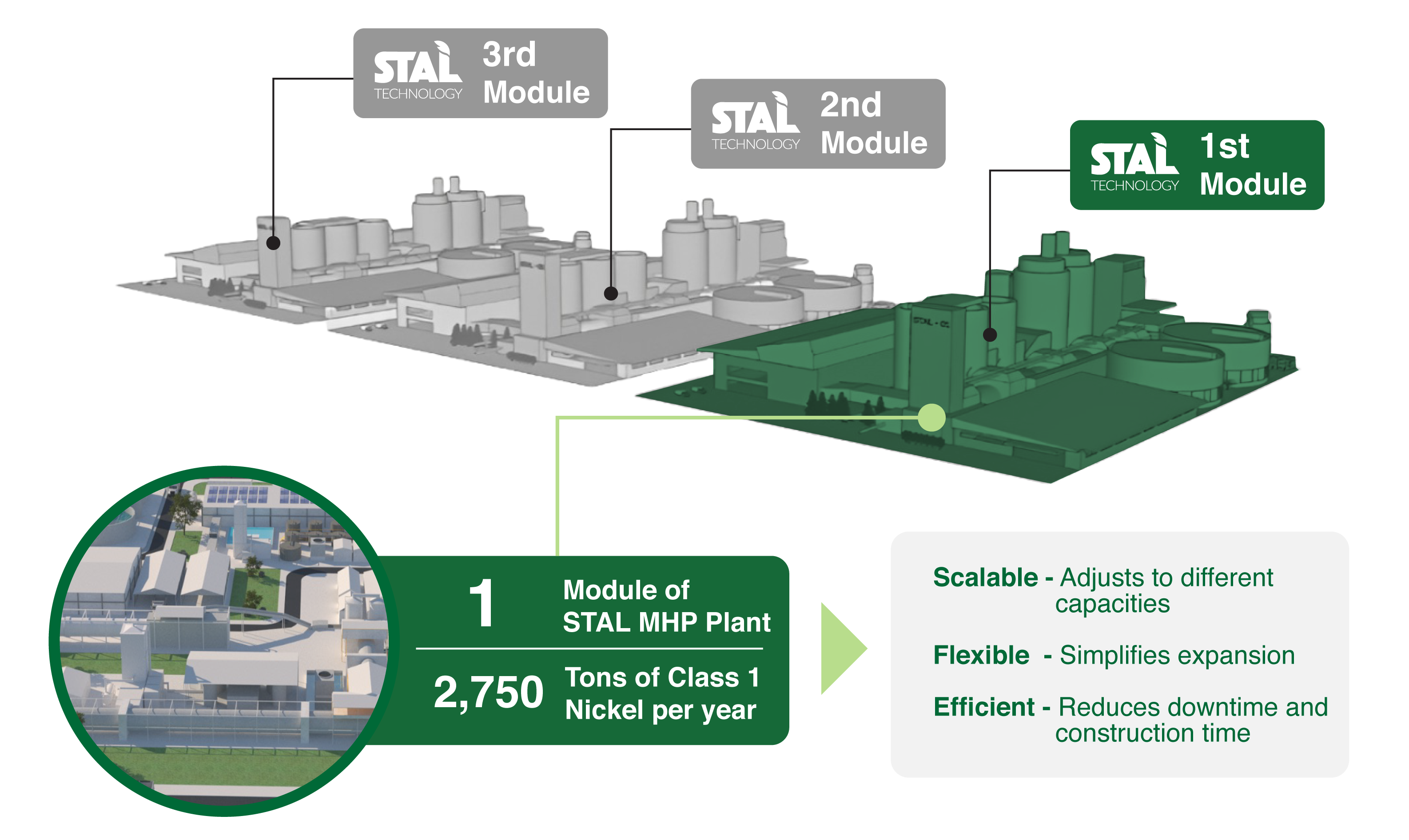

Our modular technology allows for rapid expansion and adaptation, enabling scalable solutions that meet global nickel demand efficiently. Learn how our systems can be tailored to fit diverse mining profiles and operational scales.

Dive deeper into the technological advancements that define TGEM’s approach to nickel extraction.

Webdeveloper.id menyediakan jasa pembuatan website profesional untuk bisnis Anda yang mencakup desain modern dan kekinian. Dengan pengalaman lebih dari 1500+ project dan portofolio yang kuat, kami memastikan situs web Anda akan menonjol dan memenuhi kebutuhan bisnis Anda.