At the core of sustainable energy and EV technology, Class 1 Nickel is vital. TGEM is reshaping its extraction and supply, positioning itself as a leader in the clean energy transition.

of all global passenger car sales will be EVs by 2040 1

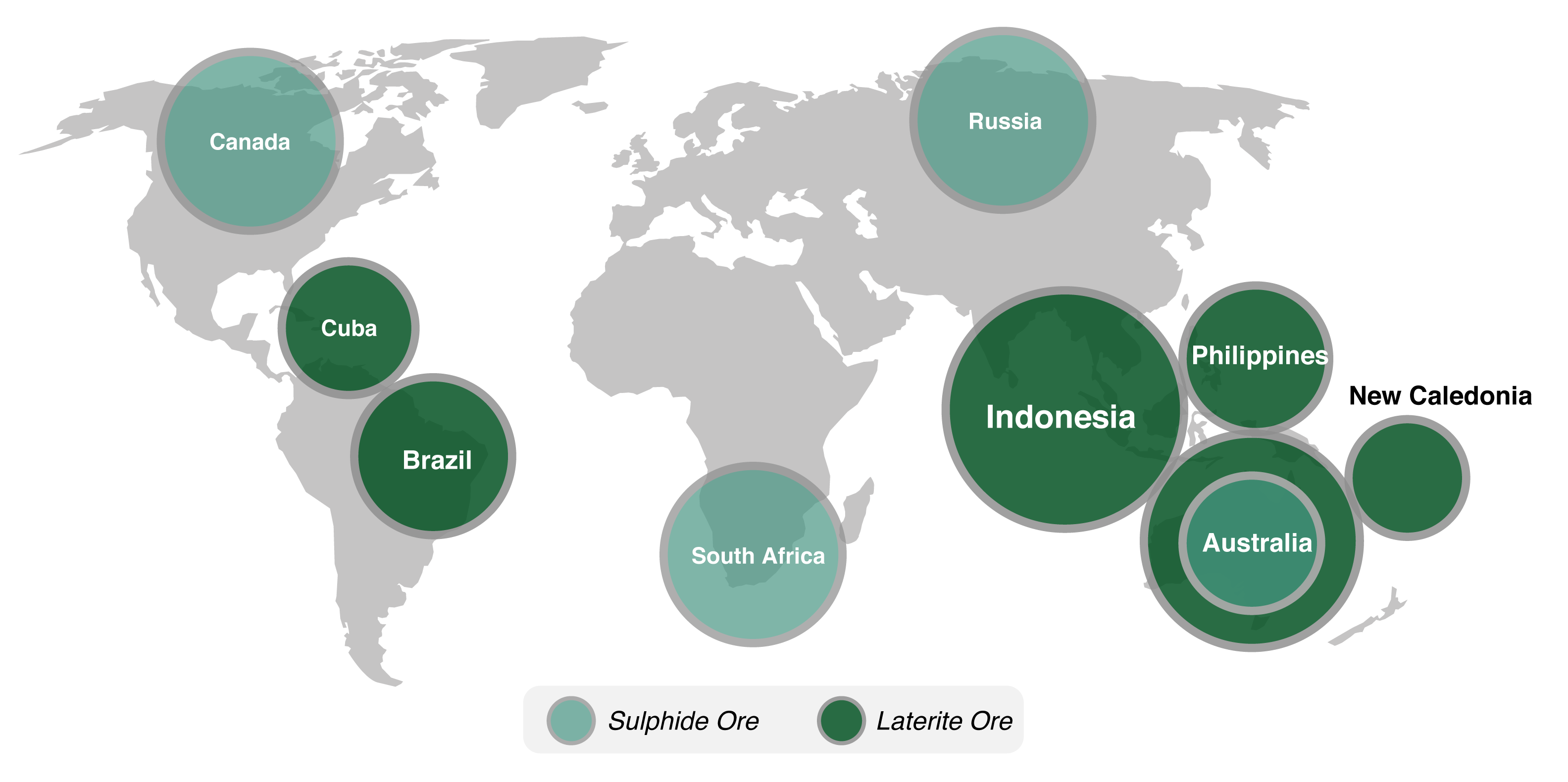

of global nickel resources are found in Indonesia, making it the largest in the world. 3

Geopolitical bifurcation of the EV supply chain (China & ROW)

The only currently available technology has multiple issues related to its carbon footprint and waste management

Source :

As the electric vehicle market expands, the demand for Class 1 Nickel surges, presenting both challenges and opportunities. The industry is urgently seeking innovative and sustainable solutions to address these challenges and support the growing demand.

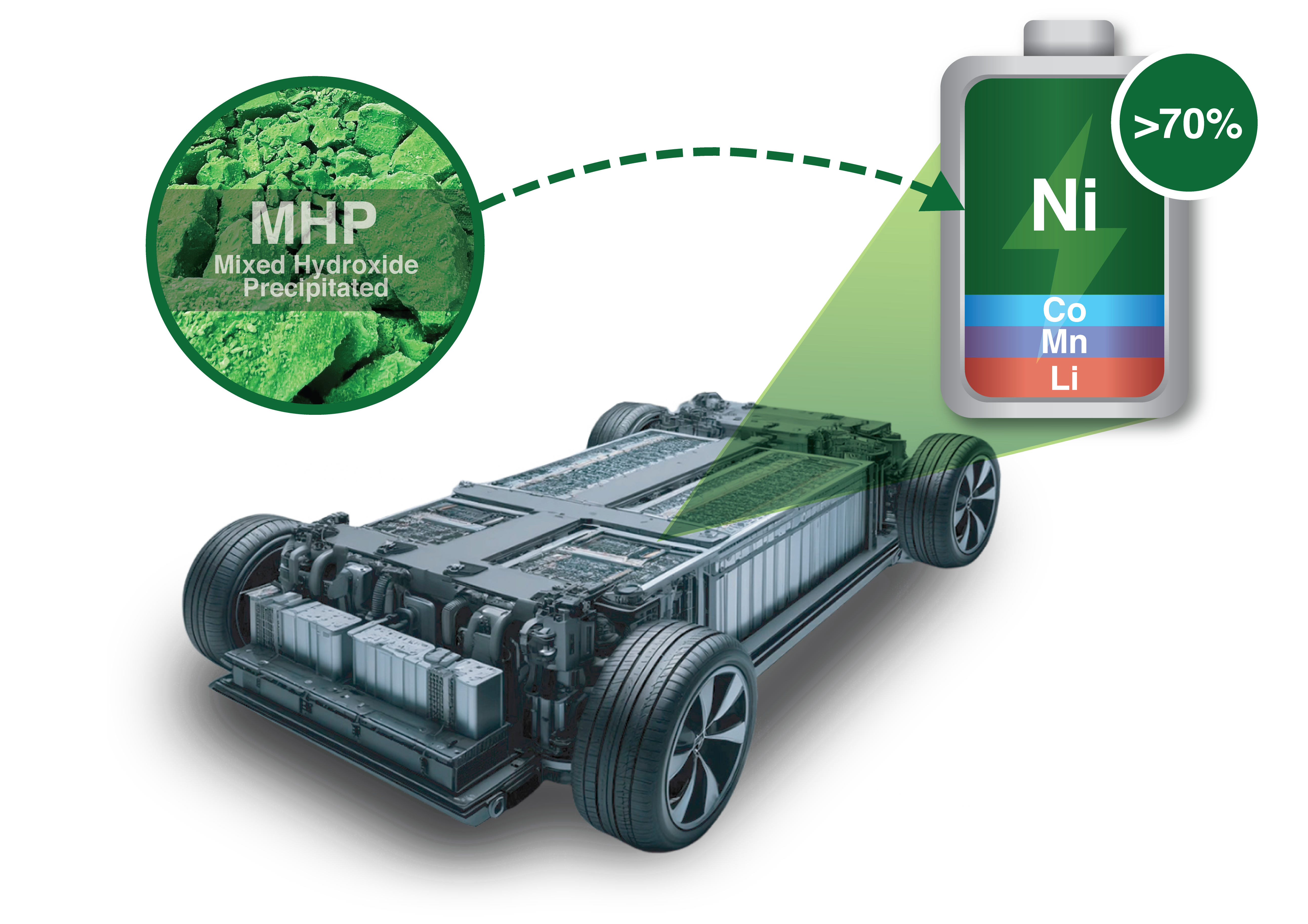

Class 1 Nickel is essential for electric vehicle batteries like NMC (Nickel-Manganese-Cobalt) and NCA (Nickel-Cobalt-Aluminum), which power most of today’s electric vehicles (EVs). As EV demand grows, Class 1 Nickel’s role in sustainable transportation becomes even more critical. TGEM’s MHP (Mixed Hydroxide Precipitate), an essential intermediate product for Class 1 Nickel with over 50% nickel content, supports this revolution.

Global reserves of nickel, led by Indonesia’s largest share, play a pivotal role in the production of high-quality Class 1 Nickel, essential for advanced battery technologies that power the future of transportation and energy storage worldwide.

Strategically based in Indonesia, TGEM leverages the country’s large laterite nickel resources to supply high-quality Class 1 nickel MHP to US and allied markets, with a strong focus on ESG and traceability.