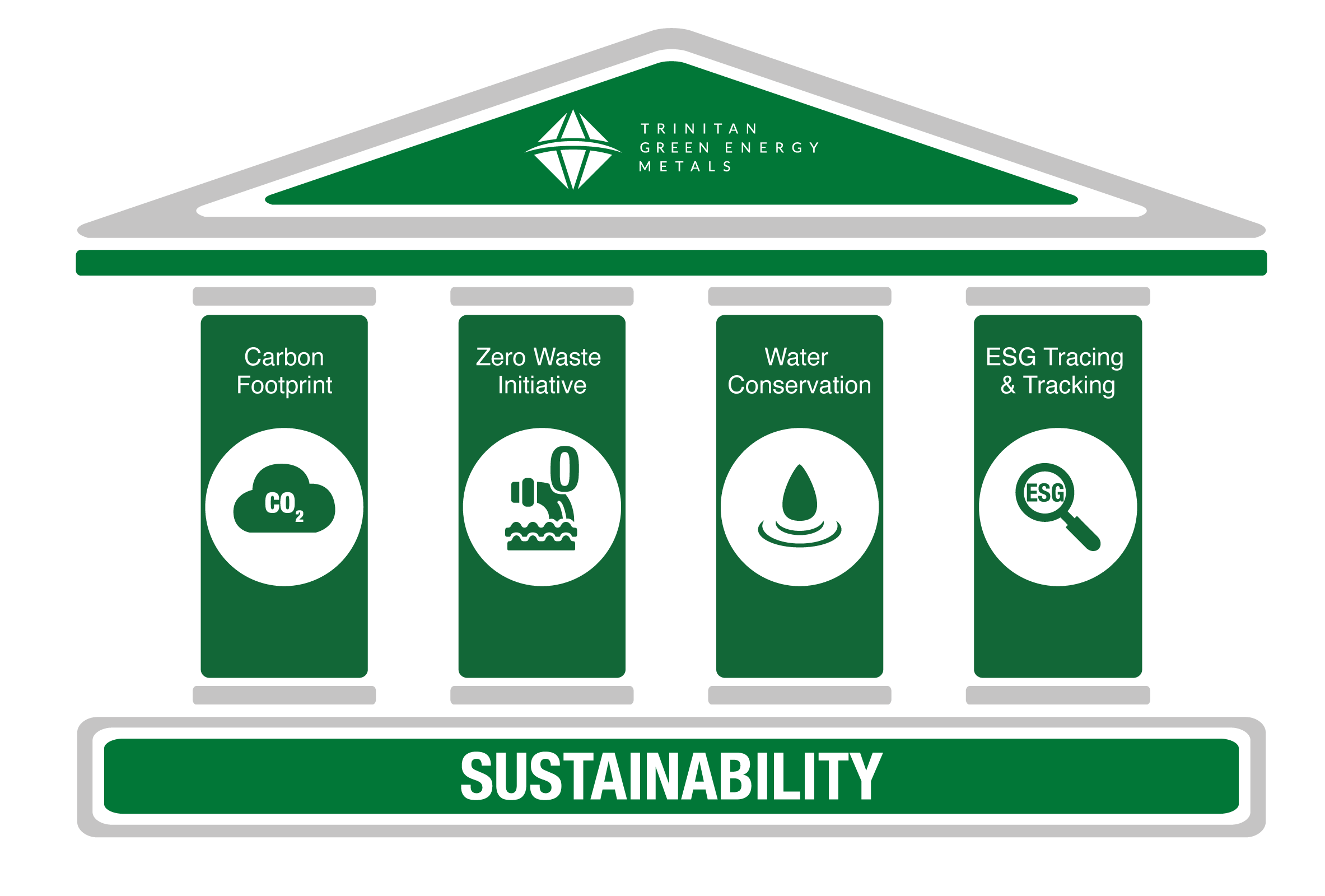

At TGEM, sustainability isn’t just part of our business — it defines our mission and drives our innovation in the nickel industry.

TGEM is built on four pillars that ensure our operations and innovations continuously enhance environmental stewardship and social responsibility.

Our STAL technology significantly lowers GHG emissions, achieving a carbon footprint more than 30% lower than typical hydrometallurgical benchmarks and more than 70% lower than common pyrometallurgical routes, supporting a shift toward lower-carbon nickel production.

Through innovative processing, all residues from our operations are converted into valuable by-products, ensuring nothing is wasted and supporting global sustainability goals.

Our process reduces water needs more than 15% compared to existing hydrometallurgical methods, reflecting our commitment to preserving natural resources.

We integrate advanced digital systems to enhance operational efficiency and transparency, ensuring compliance with global ESG standards.